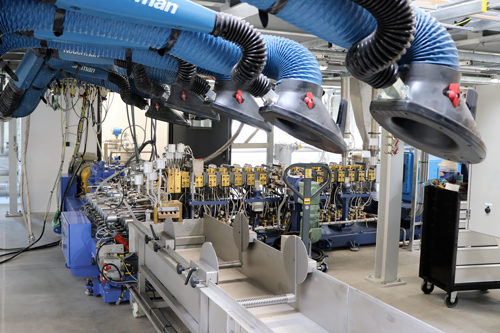

1. Extrusion Technical Center

Technical Center Machine Specification

| 1st Extruder | 2nd Extruder | |

|---|---|---|

| Application | Compounding | Devolatilization |

| Model | TEX44αⅢ | TEX30α |

| Barrel diameter (mm) | 47 | 32 |

| L/D (number of barrel) | 59.5 (17) | 45.5 (10) |

| Max. screw speed (rpm) | 1100 | 680 |

| Motor power (kW) | 185 | 22 |

2. Available processes

Our facility can offer various kind of polymer processing. Especially, we are keen on the mechanical and chemical recycling process because of high demanding plastic circularity all over the world. Nevertheless, general / special compounding, reaction and isolation (devolatilization and dewatering) process also can be offered.Recycling trial

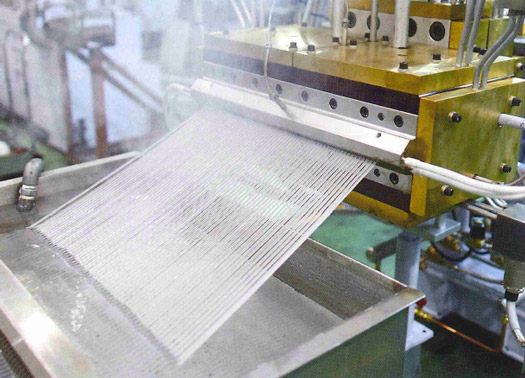

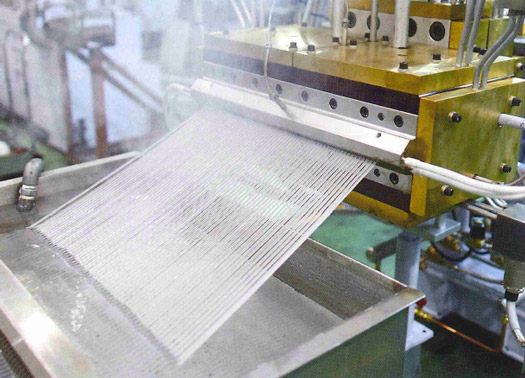

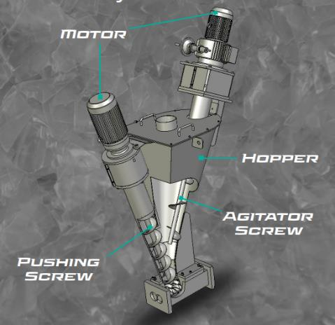

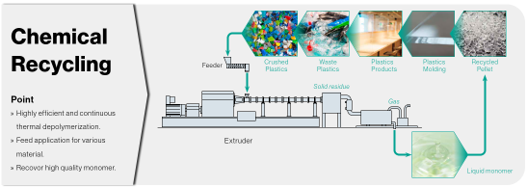

JSW is committed to advancing recycling technologies that meet today’s requirements for circularity and closed-loop systems. Our twin-screw extruders play a key role in both mechanical and chemical recycling. In mechanical recycling, special stuffing device “Compacter” enables stable feeding of low bulk density materials like shredded films, while our advanced mixing technology ensures efficient homogenization of diverse polymers and additives for effective upcycling with reduced energy consumption. In combination with a continuous melt filter, contaminants can be removed efficiently, further enhancing material quality. In chemical recycling, JSW is engaged in process research on various polymers, including PMMA depolymerization, contributing to innovative recycling pathways that support a sustainable plastic cycle.

Devolatilization trial

The combination of TEX44αⅢ and TEX30α is used. The layout of both TEX44αⅢ(1st extruder) and TEX30α(2nd extruder) is tandem, and 1st extruder is used for preparation of the solution (mixture of polymer and solvent). The polymer solution from 1st extruder is fed into 2nd extruder and then the solvent in the polymer solution is removed by vacuum pump. The removed solvent is condensed and recovered, and remained little amount solvent is burned by the incinerator, and then exhausted to outside of building safely.

Dewatering trial

Our technical center can offer the mechanical dewatering process for plastics, rubber and elastomer. And our dewatering technology can be applied to not only solution polymerization but also emulsion polymerization and suspension polymerization. JSW dewatering extruder is configurated with dewatering part and drying part all-in-one extruder. Dewatering part, most of water content can be separated from polymer solution by mechanical squeezing. And then drying part, residual moisture can be removed by vacuum drying and expansion drying.

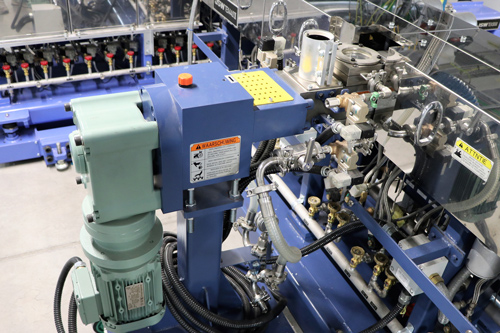

Compounding trial

TEX44αⅢ is used for compounding trial. Various types of auxiliary equipment such as Gravimetric feeders, Liquid injection pumps, Vacuum pumps, Incinerator, Water bathes, Air knife, Strand pelletizer, De-dusting system, and Side feeder are available for the trial at Extrusion Technical Center. The top of each barrel can be opened, and it means feed port and vent port can be move freely. SFD (Side feeder with vacuum degassing function) can be mounted on TEX44αⅢ for typical filler compound trial and its function is the compacting of bulky filler by vacuum during passage through the SFD.